Greetings,

Many people are hot on the “True Bypass” thing. The electronic switching as used by Boss, Ibanez, and many other popular effects is considered passé, as now people want to have their bypassed signal completely un-tainted by superfluous buffers. And in some cases they have a valid point, if you have 6 Boss pedals all strung together, your signal is going through as many as 12 buffers, and in the case of the transistor emitter-follower type as is used in these pedals (which always has slightly less than unity gain), this can result in a substantial signal loss.

So, it has become popular to modify these effects to have mechanical switches that fully bypass the signal when the effect is turned off. There is one big problem; most people seem to think the best choice of switch is the large 3PDT footswitch sold by New Sensor (or Cliff, or Fulltone…) that is popular in many DIY and boutique builds. This is generally a good quality switch, but it is LARGE, and there isn’t adequate space in the Boss Compact series case design to accommodate it. In fact, the Boss case is designed to have a large actuation plate pressing on a very small switch, so there is no space at all for anything but a very small switch. In an attempt to make the large switches fit, there have been countless examples of the attractive and functional appearance of pedal ruined by drilling holes through the actuator plate to fit the switch. You’ve seen them… these ugly things with huge footswitches sticking out of them… terrible.

But there is an elegant solution to this problem, and it’s actually quite simple – just use a small mechanical DPDT pushbutton switch that fits correctly under the actuator. You can see one here:

The only trick is to get the height of the switch plunger adjusted so that the actuator presses on it correctly. Foam rubber makes this easy.

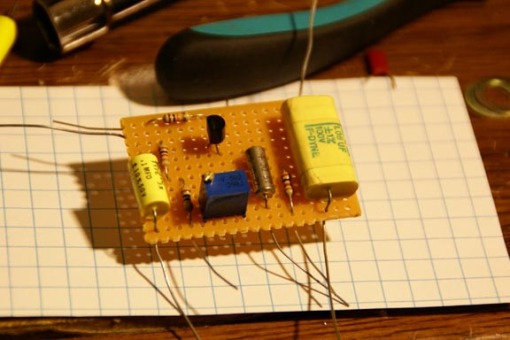

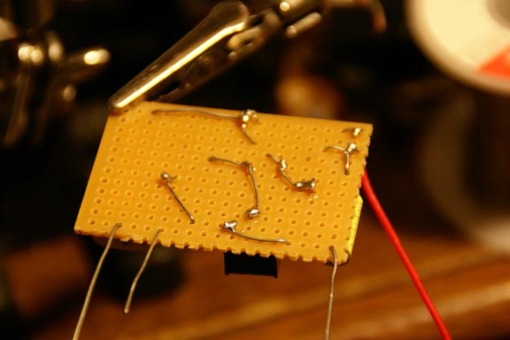

I etched a board to hold the switch and simplify connections. It is held in place by a bolt which is mounted through the stud that holds the actuator spring.

You can see a tutorial which describes using a small switch like this at Small Bear Electonics (and yes, they sell a similar switch). http://www.smallbearelec.com/HowTos/Shell/Shell.html

For switching the LED, I am using R.G. Keen’s brilliant Millenium Bypass circuit. You can read about that here: http://www.geofex.com/Article_Folders/Millenium/millen.htm

That’s it, very simple really – there is absolutely no reason to hack up a Boss pedal to put true bypass in it. And doing it this way retains much of the “soft” feeling that makes Boss’ Compact pedals such a great design.

And as for the rest of this old BF-2? I did a handful of simple mods to help to improve it. Firstly, I removed elements of the old switching circuit to accommodate the new mechanical bypass circuit. Then, I replaced the old worn-out electrolytic caps and upgraded them with better types. I also replaced the signal opamps with better low-noise types. The stock 4558s are fine for an old Tube Screamer, but they’re pretty lousy if you want a nice hi-fi sound. Some the two 1uF electrolytics in the signal path were replaced with Nichicon MUSE audiophile grade bipolar types, and a pair of 220nF caps that were previously electrolytic have been replaced with film types for a definite improvement in fidelity. That’s about all this on needed to get some good improvements and lower the noise a bit.

Here’s a pic:

I hope this little article gives you some ideas for your own mods to the Boss Compact Series. They’re really fun to work on, and little changes can sometimes go a long way.

-MC

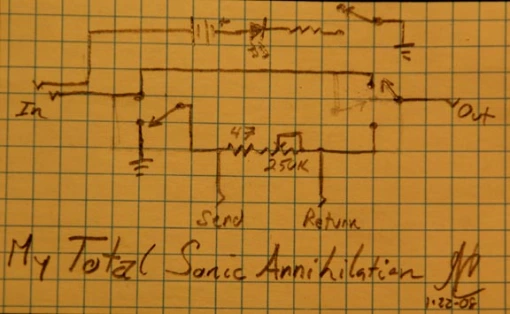

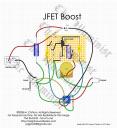

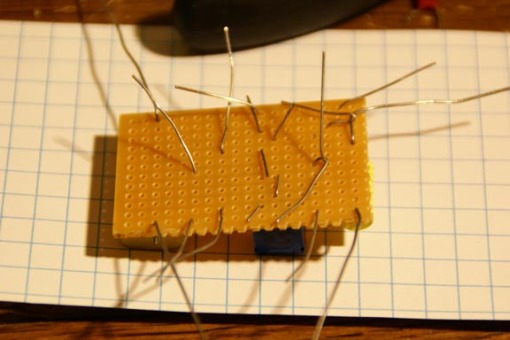

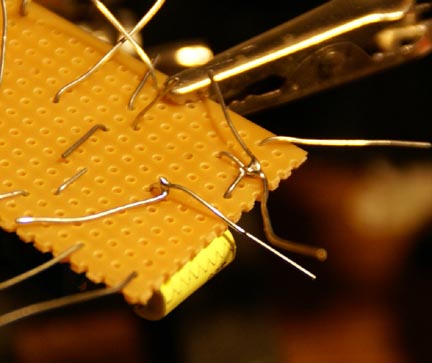

See how the leads to C1, C2, and R4 are left long and free? They will be used to make connections when the board is mounted. It provides a tight, secure connection, and helps hold the board in place.

See how the leads to C1, C2, and R4 are left long and free? They will be used to make connections when the board is mounted. It provides a tight, secure connection, and helps hold the board in place.

Now ready for…

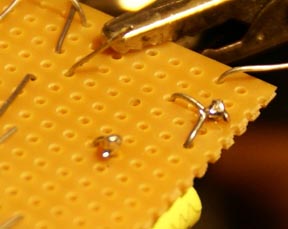

Now ready for… This sets the correct idle current for the JFET and ensures correct operation. Practitioners wanting to live dangerously can experiment with different bias currents to hear what impact it can have on the sound.

This sets the correct idle current for the JFET and ensures correct operation. Practitioners wanting to live dangerously can experiment with different bias currents to hear what impact it can have on the sound. Be kind, I reused a torn up throwaway box. This article is about being pretty on the inside.

Be kind, I reused a torn up throwaway box. This article is about being pretty on the inside.